Pulverised coal combustion (PCC) dominates the global sources of primary energy required to meet the demand for electrical base load power. Despite recent efforts to mitigate the adverse effects of thermal coal conversion such as pollutant formation and climate change, further research on the underlying physical and chemical processes of PCC is needed. PCC is a complex multiphase problem, which can be split into turbulent flow, particle transport, pyrolysis, volatile combustion, char conversion and thermal radiation. The large eddy simulation (LES) technique provides an accurate framework for the numerical simulation of turbulent flow, which is responsible for the mixing of fuel (volatiles and char off-gases) with the oxidiser stream(s) inside the furnace. The details of this turbulent fuel/oxidiser mixing ultimately determine the ignition and flame stabilisation of pulverised coal flames. This project extends the LES method, which is fairly established for pure gas flames, to pulverised coal flames and to validate the LES results against well-established experimental data on the laboratory and pilot scale.

Movie 1

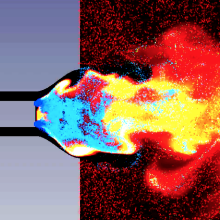

Movie 1: Large eddy simulation of pulverised coal combustion in the pilot scale facility IFRF furnace #1. The simulation employs the Euler-Lagrange approach, where the gas phase is described in the Eulerian framework, whereas parcels of coal particle are tracked in the Lagrangian framework. A cross-section through the centre of the computational domain is shown. Combustion air for coal oxidation is provided through an annular swirling stream (black) from the left. Coal and carrier gas are injected through a concentric annular pipe (not part of the simulation) located inside the combustion air stream. The Eulerian gas temperature is shown in greyscale. The coal parcels are coloured by their mass fraction of ash, where low levels of ash (blue) indicate freshly injected particles and ash mass fractions of unity represent full particle burnout.

Related publications

- Y. Chen, O. T. Stein, A. Kronenburg, J. Xing, K. Luo, K. H. Luo, and C. Hasse, “Analysis of Gas-Assisted Pulverized Coal Combustion in Cambridge Coal Burner CCB1 Using FPV-LES,” Energy & Fuels, vol. 34, pp. 7477–7489, (2020).

- G. Olenik, O. T. Stein, and A. Kronenburg, “LES of swirl-stabilised pulverised coal combustion in IFRF furnace No. 1,” Proc. Combust. Inst., vol. 35, pp. 2819–2828, (2015).

- O. T. Stein, G. Olenik, A. Kronenburg, F. Cavallo Marincola, B. M. Franchetti, A. M. Kempf, M. Ghiani, M. Vascellari, and C. Hasse, “Towards Comprehensive Coal Combustion Modelling for LES,” Flow, Turbul. Combust., vol. 90, pp. 859–884, Jun. (2013).

- G. Olenik, O. T. Stein, and A. Kronenburg, “LES of an industrial scale swirled pulverised coal furnace,” in 26th German Flame Day, VDI-Tagungsband 2161:235-242, (2013).

- G. Olenik, O. T. Stein, and A. Kronenburg, “LES of a piloted pulverized coal jet,” in 1st ERCOFTAC Conf. on Simul. of Multiphase Flows in Gasific. and Combust., Dresden, Germany, (2011).

Contact

Oliver T. Stein

Dr.former deputy director