Fractal aggregates are encountered in numerous applications such as particle flame synthesis, spray-drying and water purification where their individual size and morphology is directly linked with the properties of the final product. In these applications, aggregation occurs due to adhesion of particles upon collision. In general, collision events, caused by a relative motion between particles, can have various underlying mechanisms depending on process conditions and particle sizes. In the context of particle flame synthesis, these mechanisms are mainly associated with Brownian motion and the presence of a turbulent flow field. Regarding the simulation of aggregate growth dynamics in such a system, a statistical approach in the form of a population balance equation, from which a size distribution can be drawn, is typically favored given the large number of particles. This approach requires an accurate model for the collision frequency of aggregates which is the focal point of this research project.

Current models are found to be unsuitable for this task as they either cover only a limited size range and a single aggregation mechanism or consider spherical aggregates. However, fractal aggregates may grow by several orders of magnitude in size implying that different aggregation mechanisms are dominant throughout different sections of the growth process. It is the multi-scale nature of the aggregation process that is the most challenging part of this project. Furthermore, fractal aggregates can exhibit complex shapes which strongly impact their collision probability and thus, the assumption of spherical aggregates is prone to large errors.

The validation of derived collision frequencies poses the second crucial part of this project. As experiments do not allow for a detailed comparison, a direct method implemented in OpenFOAM is utilized to track individual particles and respect the complex shape of fractal aggregates. Compared to previous implementations aggregates are treated as rigid bodies which avoids the introduction of complex bonding force fields. Given their computational effort, detailed simulations can only cover a relatively small size spectrum, i.e. a model validation is restricted to this particular size range. In order to tackle the multi-scale issue, a coarse-grained model is utilized to close the gap from the smallest primary particle scales to the larger turbulent length scales by summarizing aggregates into a new representative one. The reduced complexity allows to incorporate realistic turbulent flow fields but discards detailed information about the aggregate. Hence, coarse-grained particles inherit several characteristic parameters that help assigning a collision probability.

Movie 1

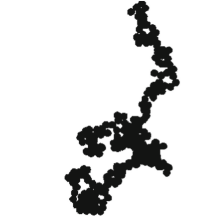

Langevin dynamics simulation of nanoparticle agglomeration. A total number of 100 identical agglomerates of 40 nanoparticles each, with a radius of gyration and fractal dimension of 3 and 1.6, respectively, is placed in the cubic computational of size 90 particle diameters as initial condition. During the simulation, which employs periodic boundary conditions, the agglomerates are able to move due to random motion and fluid flow. Cluster-cluster collisions and sticking lead to a decrease of the total number of clusters with time until only very few larger agglomerates remain.

Movie 2

Movie 2: Coarse-grained simulation corresponding to the same initial conditions as for Movie 1. Each of the spherical coarse-grained particles represents a (statistically) realistic agglomerate from the Langevin dynamics simulation. The cluster-cluster collision probability is extracted from the Langevin dynamics data and used for the coarse-grained simulation approach.

Related publications

- M. Karsch and A. Kronenburg, “Modelling nanoparticle agglomeration in the transition regime: A comparison between detailed Langevin Dynamics and population balance calculations,” Journal of Aerosol Science, vol. 173, p. 106228, (2023).

- W. Qian, A. Kronenburg, X. Hui, Y. Lin, and M. Karsch, “Effects of agglomerate characteristics on their collision kernels in the free molecular regime,” Journal of Aerosol Science, vol. 159, p. 105868, (2022).

- M. Karsch, A. Kronenburg, and O. T. Stein, “Coagulation rate coefficients for fractal-like agglomerates in the diffusive and ballistic limits,” Chemical Engineering Research and Design, vol. 187, pp. 611--622, Nov. (2022).

- S. Hirschmann, A. Kronenburg, C. W. Glass, and D. Pflüger, “Load-Balancing for Large-Scale Soot Particle Agglomeration Simulations,” in Parallel Computing: Technology Trends, (2020), pp. 147--156.

- M. Smiljanic, R. Weeber, D. Pflüger, C. Holm, and A. Kronenburg, “Developing coarse-grained models for agglomerate growth,” The European Physical Journal Special Topics, vol. 227, pp. 1515–1527, Mar. (2019).

- M. Smiljanic, A. Kronenburg, R. Weeber, C. Holm, and D. Pfüger, “Towards a coarse-grained approach for nanoparticle agglomeration,” in Proc. 6th Internat. Conf. on Population Balance Mod., Ghent, Belgium, (2018).

- G. Inci, A. Kronenburg, R. Weeber, and D. Pflüger, “Langevin Dynamics Simulation of Transport and Aggregation of Soot Nano-particles in Turbulent Flows,” Flow, Turbul. Combust., pp. 1065–1085, (2017).

- G. Inci, A. Arnold, A. Kronenburg, and R. Weeber, “Modeling Nanoparticle Agglomeration using Local Interactions,” Aerosol Sci. and Technology, vol. 48, pp. 842–852, (2014).

- G. Inci, A. Kronenburg, and A. Arnold, “Characteristics of soot aggregation in convective environments,” in 10th Symp. Eng. Turbul. Mod. and Meas. (ETMM), Marbella, (2014).

- G. Inci and A. Kronenburg, “Particle Aggregation: A Comparison between Molecular Dynamics Simulations and Modelling by the Population Balance Equation,” in Proc. 5th Internat. Conf. on Population Balance Mod., Bangalore, India, (2013).

- G. Inci and A. Kronenburg, “Modelling aerosol agglomeration using molecular dynamics methodology,” in 2013 Europ. Aerosol Conf. (EAC 2013), Prague, Czech Republic, (2013).

Contact

Andreas Kronenburg

Univ.-Prof. Dr.Director of the Institute

Maximilian Karsch

Scientific staff